Dryer Gas Valve Mysteries & Secrets Revealed

September 9, 2010 Leave a comment

In this article I will explain the different style gas valve and ignition systems and reveal to how they work.

Glo-sil Burner Assembly.

The first type of Glo-sil burner used until 1984 was the ‘K’ series pictured below. In 1984 production shifted to the ‘M’ series. The look different but function in the same way.

Burner Components

Split coil solenoid is used to operate the first of the two valves. Both coils must be energized for the valve to be opened.

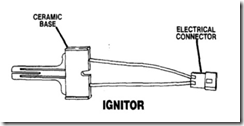

The Ignitor (glow rod) heats to a temperature of about 2200 degrees F in about 15 to 30 seconds after voltage is applied to it. Several different styles have been made but they all function the same way.

Radiant Sensor is mounted on the side of the burner funnel. A cut-out in the funnel allows radiant heat from the ignitor and gas flame to contact the sensor. Its contacts are single pole, single throw and are calibrated to open when the ignitor reaches 2200 degrees F. Heat from the burner holds the contacts open after ignition.

Burner Operation

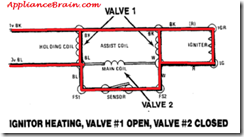

When voltage is applied, a circuit is completed from 1 V to the ignitor and sensor back to 3V. At the same time the assist coil and holding coil are energized. Both of these coils must have full line voltage (120 Volts AC) applied to lift valve number one of its seat. This action means that the ignitor is heating and one valve is open. No gas can flow yet until valve number two opens. The number two (Main) coil is not energized because current is shunted through the sensor. (Path of least resistance.

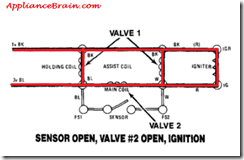

When the ignitor reaches a temperature hot enough to open the the radiant sensor contacts, the only path left is through the number two (Main) coil. This causes valve number 2 to open. Gas now flows through the valve and is ignited instantly by the hot ignitor. At this time magnetism from the Assist coil is reduced but the holding coil is enough to keep the valve open.

If voltage to the burner is momentarily interrupted and then restored, the number 2 valve will open. With the reduced current through the assist coil, now in series with the 2 coil, the number 1 valve will not open. When the sensor cools and the contacts reclose, re-ignition will re-occur.

To order parts for your dryer visit www.ApplianceBran.com

Technorati Tags: Dryer,Valve,ignition,Burner, Components,Ignitor,temperature ,voltage,Sensor, Heat,Operation,circuit,Volts

Windows Live Tags: Dryer,Valve,ignition,Burner, Components,Ignitor,temperature, voltage,Sensor, Heat,Operation,circuit,Volts

WordPress Tags: Dryer,Valve,ignition,Burner ,Components,Ignitor,temperature, voltage,Sensor ,Heat,Operation,circuit,Volts

Blogger Labels: Dryer,Valve,ignition,Burner, Components,Ignitor,temperature, voltage,Sensor, Heat,Operation,circuit,Volts